Web Based Remote Monitoring

Reliable Web based solutions for monitoring the condition or status of remote assets no matter where you or they are located.

Read more...

Reliable Web based solutions for monitoring the condition or status of remote assets no matter where you or they are located.

Read more...

SIL rated alarms systems, wireless telemetry and web based inventory tracking systems. Connects to your existing tank gauging.

Read more...

Advanced proven Impressed Current Cathodic Protection Systems incorporating Remote Monitoring and Control. New or retrofit existing sites.

Read more...

Specialised monitoring systems for Radiological environments including

nuclear power stations, storage facilities, PET

Centres etc.

Read more...

Real time energy, water, gas, air and/or steam monitoring for industry, commercial buildings and campuses. Meets reporting standards and reduces cost.

Read more...

Remote Temperature monitoring systems tailored for pharmaceutical and food industry applications from laboratories to warehousing. Meets reporting standards.

Read more...

Process Alarm Systems to IEC61508 and Event recording to sub-millisecond resolution making plants safer and reducing downtime.

Read more...

Upgrade your legacy alarm systems to current safety standards with minimum plant disruption. Custom solutions to suit individual needs.

Read more...

Data2Desktop provides an end-to-end solution to your remote

monitoring needs. Data2Desktop relieves you of the technical

complexities of implementation, with rapid low risk deployment.

Turn your organisation into a Real Time Enterprise within days.

more...

Remote Monitoring Specialists

Instrument PSUs

Priced to perfection

DIN Rail mounted

All Round Protection

Adjustable 24Vdc o/p

Home > Press Release

FOR IMMEDIATE RELEASE

|

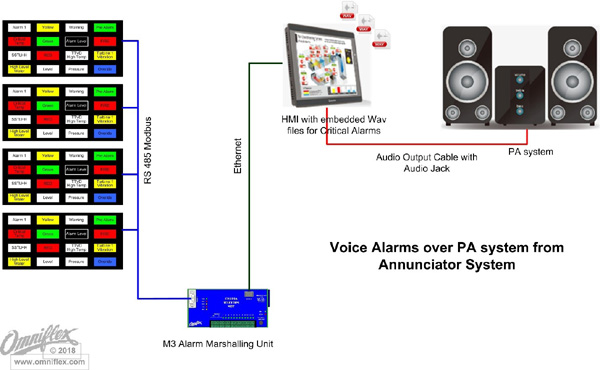

Alarm Overload is an issue most control rooms must deal with on an ongoing basis. Relieving operator overload is a major priority for most process engineering professionals. Much of the burden has been caused by DCS and SCADA systems delivering too much information to operators who are then under pressure to make decisions and take corrective action. Whilst it’s not disputed that all this information is important to a smooth-running process, it’s important to differentiate between the types of information collected by the supervisory systems and to classify alarms requiring action from status information. The role of the alarm system is to prompt operator intervention to act and return the process to optimum levels or to safe conditions. Critical Alarms are most often managed with the use of Annunciators as a separate layer of plant protection over and above the Supervisory system. However even this methodology does not always reduce the load on operators who are trying to service alarms coming into the control room. Standards like ISA 18.1 and EEMUA 191 Alarm Systems are extremely valuable in rationalizing the alarm management process however they are generic, and every plant or process has its own unique issues when it comes to abnormal conditions. Many schools of thought have sought to relieve the pressure on operators in those cases and they often boil down to differentiating the types of alarm using audio visual stimuli. An option requested from a client to take the current plant alarm system and rationalize that into voice alarms over the PA system that busy operators can hear and evaluate the urgency of without leaving what they are currently busy with was the real benefit to operator efficiency. Alarms are voice recorded into WAV files and embedded on the HMI ready to be triggered by the Alarm Marshalling unit which is monitoring the existing alarm systems. This could be a PLC or SCADA as well as existing Omni16 Annunciator system. An Alarm banner on the HMI further provided information on the Alarm. Un resolved alarms will also reflash after a period of time to remind operators of their status and importance. Benefits:

Solve all your Alarming needs today! For more information on our range of Annuciators, click here! |

Back to PR Listing

For further information on this press release please contact sales@omniflex.com

Product Ranges

Overview of typical Voice Alarm System

Overview of typical Voice Alarm System