Web Based Remote Monitoring

Reliable Web based solutions for monitoring the condition or status of remote assets no matter where you or they are located.

Read more...

Reliable Web based solutions for monitoring the condition or status of remote assets no matter where you or they are located.

Read more...

SIL rated alarms systems, wireless telemetry and web based inventory tracking systems. Connects to your existing tank gauging.

Read more...

Advanced proven Impressed Current Cathodic Protection Systems incorporating Remote Monitoring and Control. New or retrofit existing sites.

Read more...

Specialised monitoring systems for Radiological environments including

nuclear power stations, storage facilities, PET

Centres etc.

Read more...

Real time energy, water, gas, air and/or steam monitoring for industry, commercial buildings and campuses. Meets reporting standards and reduces cost.

Read more...

Remote Temperature monitoring systems tailored for pharmaceutical and food industry applications from laboratories to warehousing. Meets reporting standards.

Read more...

Process Alarm Systems to IEC61508 and Event recording to sub-millisecond resolution making plants safer and reducing downtime.

Read more...

Upgrade your legacy alarm systems to current safety standards with minimum plant disruption. Custom solutions to suit individual needs.

Read more...

Data2Desktop provides an end-to-end solution to your remote

monitoring needs. Data2Desktop relieves you of the technical

complexities of implementation, with rapid low risk deployment.

Turn your organisation into a Real Time Enterprise within days.

more...

Remote Monitoring Specialists

Instrument PSUs

Priced to perfection

DIN Rail mounted

All Round Protection

Adjustable 24Vdc o/p

Home > Press Release

FOR IMMEDIATE RELEASE

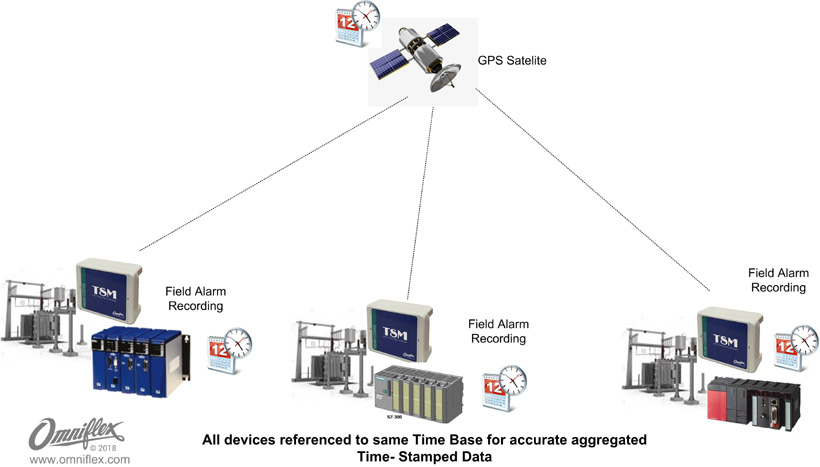

Managing processes where root cause identification is rapidly identified can generate substantial savings though improved productivity and implementation of planned preventive maintenance schedules. Knowing what happened first in a chain of events in the plant quickly leads to the appropriate corrective action. Omniflex has spent 50+ years in Alarm and Event management system design and development providing 1 milli-second discrimination to trip alarming status enabling the plant to quickly identify root cause. Our “Time Stamp at Source” philosophy immediately differentiated our trip recording by being far more accurate than supervisory system PC or DCS time stamping which is unable to account for propagation delay of network signal and the I/O scanning ability of the front-end devices. The more I/O the longer it takes! Omniflex adopted a fixed scan cycle (independent of I/O count) and a time stamp at source for every change of state, having a GPS time synchronized clock source provides unparalleled alarm time accuracy right where it’s needed.

Many time synchronizing standards have been used over the years from pulse inputs to IRIGB popular in the electrical field and more modern Plants adopting the NTP server technology (Network Time Protocols) technology on networks or IEEE1588 Protocols to bring all time stamping to a single time base. All of which require a significant investment in hardware and software and even dedicated networks in some cases to provide plantwide synchronization.

The hard part is affordability in remote or isolated plant and getting a cost-effective solution to time synchronization. Sub Stations, Pumping Stations or remote process plants away from the main plant which often need to be reviewed on the same time base as they are inter-related.

The Omniflex TSM enables any isolated programmable equipment to synchronize its real time clock to satellite time, our sequential events recorder Maxiflex can thus provide 1milli-second discrimination to chains of events at different geographic locations and when this data is overlaid the root cause can be quickly be un-covered as the time base is down to 1millisecond resolution. Any programmable device (PLC) with a serial port can be configured to get real time from the Omniflex TSM.

Features

Benefits

Click here for more information on the Maxiflex TSM Module.

|

|

For further information on this press release please contact sales@omniflex.com

Product Ranges